T2150 Special Deephole Drilling Boring Machine for Energy Wind Spindle Motor

Umshini Uhlamvu

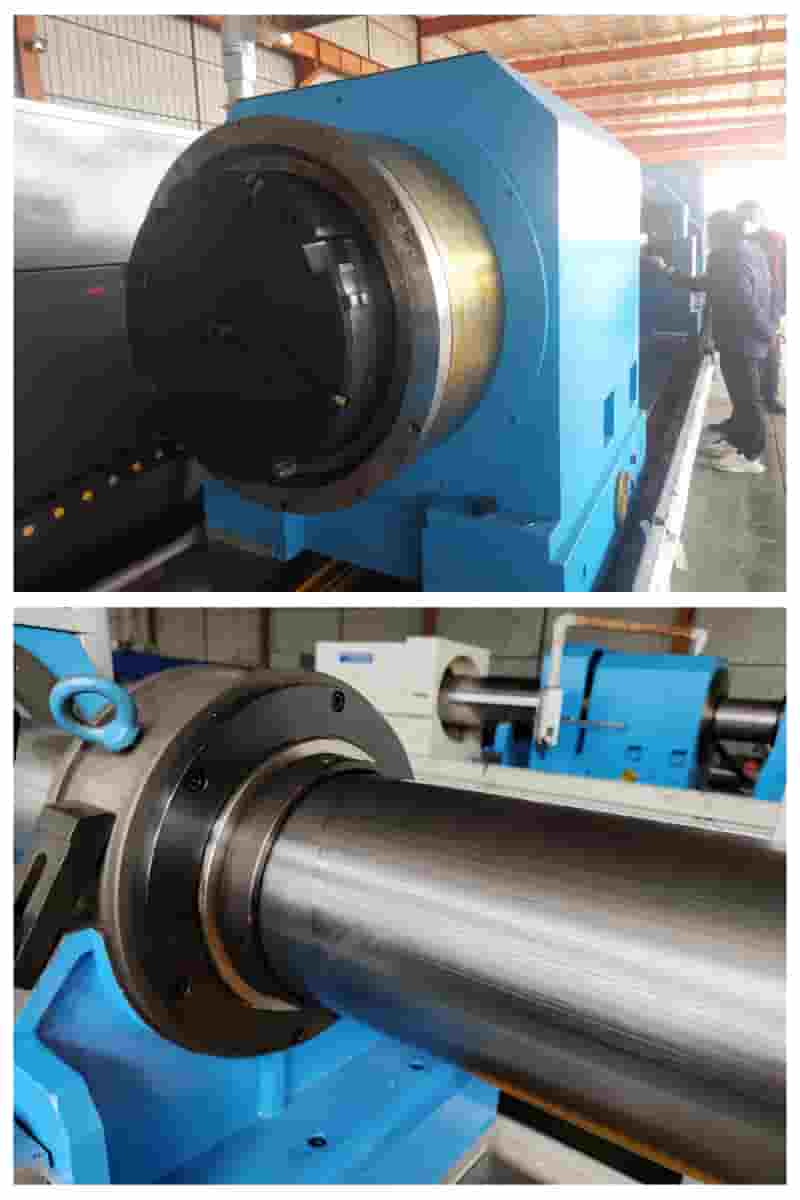

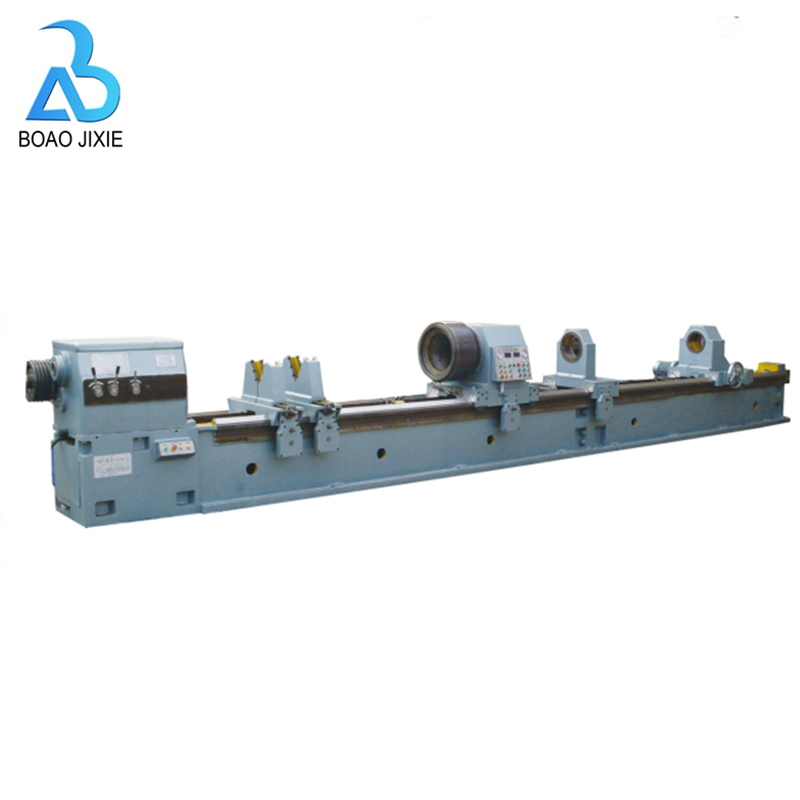

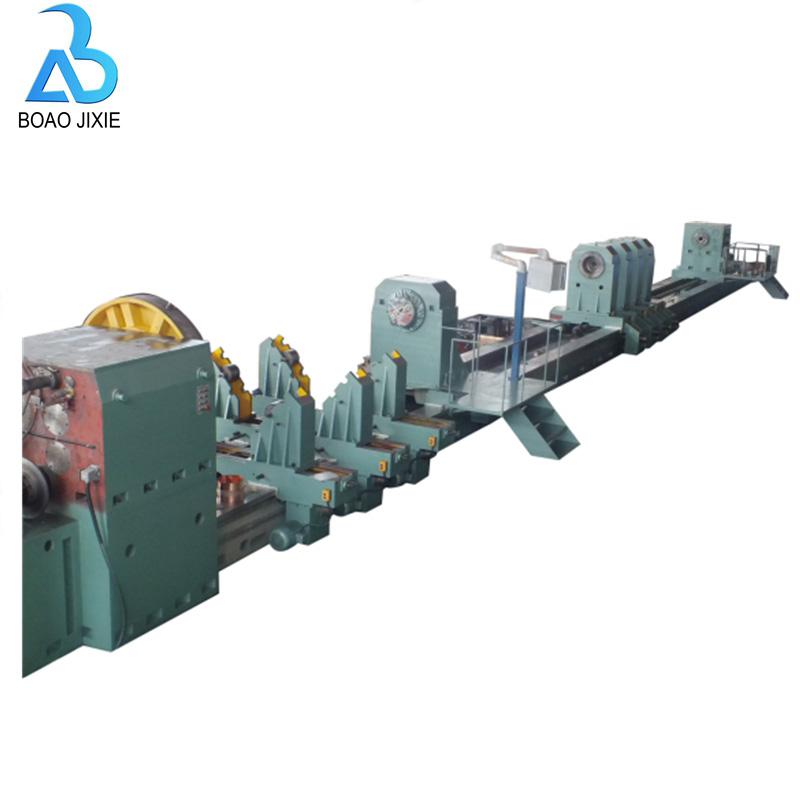

I-T2150 umshini wokumba imbobo ejulile kanye nomshini oyisicefe wuchungechunge olusindayo lwethuluzi lomshini womgodi ojulile othuthukiswe inkampani yethu ngokwezimpawu zokucubungula zemishini yamanje yokuphotha amandla omoya kanye nezidingo zemakethe.Ithuluzi lomshini ngokwalo linokuqina okuqinile futhi ligcina ukunemba okuhle.I-spindle isebenzisa ukulawulwa kwesivinini esinamajubane amathathu (esiphezulu, esingenalutho, esiphansi), nebanga lejubane libanzi.Uhlelo lokuphakelayo lushayelwa i-AC servo motor enamandla amakhulu, engahlangabezana nezidingo zezinqubo ezihlukahlukene zokucubungula imigodi ejulile..I-oiler isetshenziselwa ukuqinisa i-workpiece ngedivayisi yomshini, ephephile futhi enokwethenjelwa.Ithuluzi lomshini lingaqedela ukubhoboza, ukubhoreka, ukukhulisa nokugingqa izingxenye zembobo ejulile enobubanzi obukhulu.Ngesikhathi sokucubungula, i-workpiece ijikeleza ngesivinini esiphansi, futhi ithuluzi lijikeleza futhi lidla ngesivinini esikhulu.Lapho ubhoboza, sebenzisa indlela yezobuchwepheshe yokususwa kwe-chip ku-BTA;lapho unesithukuthezi, sebenzisa indlela yezobuchwepheshe yokuhlinzeka ngoketshezi lokusika kubha eyisicefe kanye nokukhipha uketshezi lokusika nokufaka insimbi phambili (ukuphela kwekhanda);ngokwezidingo zokucubungula, ithuluzi lomshini lifakwe ibhokisi le-drill Rod, ithuluzi lingashintshwa futhi londliwe.Ithuluzi lomshini lihlanganisa ikakhulukazi umbhede, ibhokisi lekhanda lombhede, ibhokisi lepayipi lokubhoboza, i-oyela yokuphakelayo, isistimu yokuphakelayo, ifreyimu yesikhungo socezu lokusebenza, ubakaki we-workpiece, ukusekelwa kwebha eyisicefe, inqola yokuphakelayo, isistimu yokupholisa (enedivayisi yokususa i-chip), isistimu ye-hydraulic.Leli thuluzi lomshini lingakhetha ngokuguquguqukayo indlela yokucubungula ngokuya ngezidingo zangempela, futhi linenhlobonhlobo yezinhlelo zokusebenza.

| NO | Izinto | Incazelo |

| 1 | Uchungechunge lwemodeli yomshini | T2150 |

| 2 | Ukubhoboza ububanzi | Φ30-120mm |

| 3 | I-diameter eyisicefe ikhala | Φ220-500mm |

| 4 | Ukujula okuyisicefe | 1-12m |

| 5 | Ububanzi be-clamping yokulungisa | Φ1600mm |

| 6 | Ukuphakama kwesikhungo sokuphotha komshini | 900mm |

| 7 | Isivinini se-Headstock spindle | 1-225 r/m , 3 amagiya, stepless |

| 8 | Ububanzi bembobo yokuphotha | Φ130mm |

| 9 | Idayamitha yembobo ye-pindle yangaphambili | 140 # |

| 10 | Ibha eyisicefe yebhokisi lomgodi wokuphotha ububanzi | Φ120 |

| 11 | Ibhokisi eliyisicefe lebhokisi lokuphotha elingaphambili le-taper hole | 140#, 1:20 |

| 12 | Ijubane lokuphotha lebhokisi eliyisidina | 20-400 rpm, 6 amaqabunga |

| 13 | Pallet ngokushesha ezihambayo isivinini | 2m/min |

| 14 | Ibanga lejubane lokuphakelayo | 5-1000mm/min, engenasinyathelo |

| 15 | Injini eyinhloko | 45 kw |

| 16 | Isithukuthezi se-bar motor | 22KW |

| 17 | Okuphakelayo amandla emoto | 1.5kw |

| 18 | Ukondla inqola ngokushesha motor amandla | 5.5KW |

| 19 | Injini yepompo epholile | N=5.5kw ( 3 amaqembu) |

| 20 | Ingcindezi elinganiselwe yesistimu epholile | 2.5Mpa |

| 21 | Ukugeleza kwesistimu yokupholisa | 100, 200, 500 L/min |

| 22 | Isistimu epholile elinganiselwe ingcindezi | 6.3 Mpa |

| 23 | Ukulayishwa okuphezulu kwamandla e-eksisi | 6.3 Kn |

| 24 | I-Max oiler fixing force ye-workpiece | 20KN |

| 25 | Isisindo esiphezulu sokulayisha emshinini | 20T |

| 26 | Isistimu yokulawula | I-Siemens 808 noma i-KND |

Izingxenye Zomshini Ezibalulekile