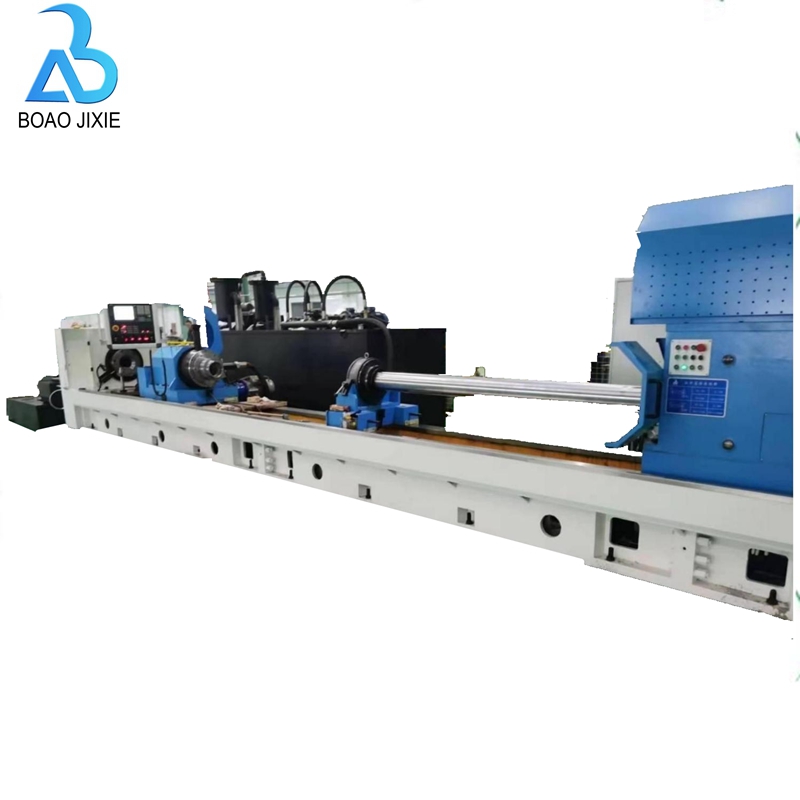

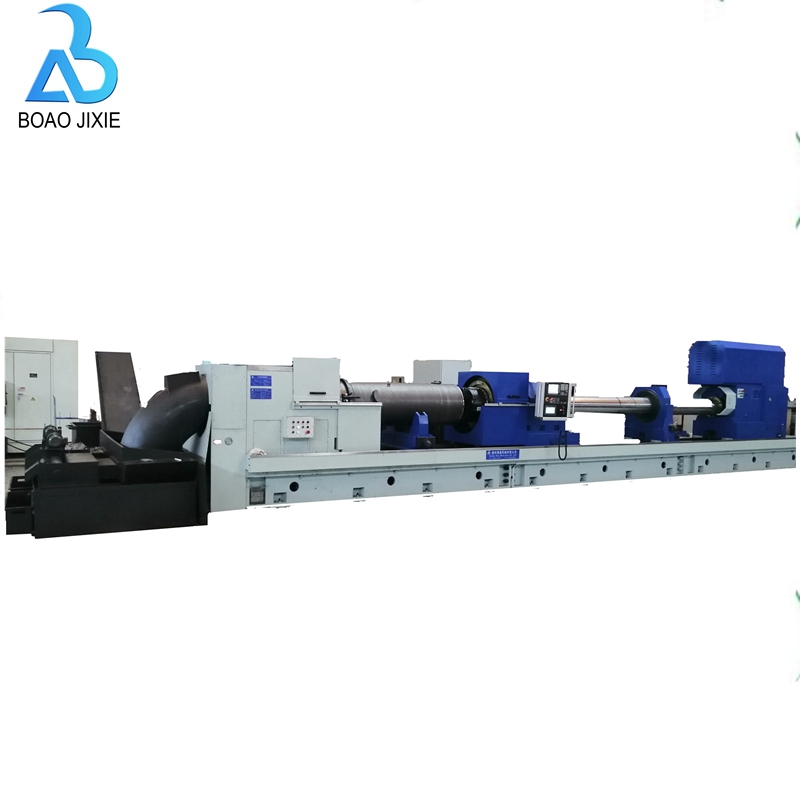

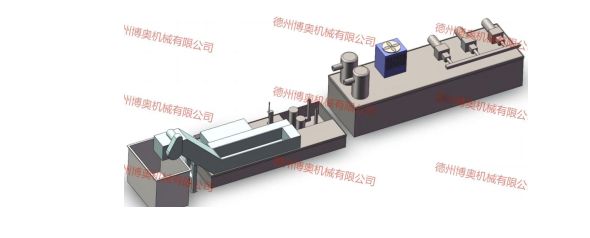

TGK25 Deep Hole CNC Scraping & Rolling Machine

Umshini Uhlamvu

Amathuluzi omshini wochungechunge lwe-TGK25 afaneleka ngokukhethekile ukucutshungulwa kwenqwaba yamasilinda ahlukahlukene we-hydraulic, amasilinda nokunye ukufakwa kwamapayipi okunembayo.Amakhasimende ethu aseShayina asebenzisa imishini yethu ukukhiqiza inani elikhulu lokufakwa kwamapayipi okunembayo.Leli thuluzi lomshini lifakwe inombolo enkulu yezingxenye zikagesi ezisebenza kahle kakhulu, okwenza i-rolling scraper ibe nokusebenza okuzinzile, ibone izidingo ezihlukahlukene zobuchwepheshe bokucubungula okuyinkimbinkimbi, futhi inikeze ukusebenza kahle kokusika okuphezulu.Amakhasimende ethu aseShayina aneliseke kakhulu ngalo mshini womgodi ojulile oyisicefe, osenza sizuze amakhasimende amaningi.Le mishini iphinde ibe uchungechunge lomkhiqizo oyinhloko olunconywe inkampani yethu ezinkampanini ezinkulu zokuhweba ukuze zithunyelwe ngaphandle.

Amapharamitha womshini

| NO | Izinto | Incazelo |

| 1 | Icubungula Ibanga Lobubanzi Bangaphakathi | Φ40-250mm |

| 2 | Icubungula Ibanga Lokujula | 150mm-12000m |

| 3 | Ububanzi Bendlela Yomshini | 650 mm |

| 4 | Spindle Center Ukuphakama | 350mm |

| 5 | Isivinini Sophiko, Amabanga | 120-1000rpm, 4 amagiya, stepless |

| 6 | I-Main Motor | 45KW, AC servo motor |

| 7 | Ibanga Lesivinini Sokudla | 5-3000mm/min (engenasinyathelo) |

| 8 | Isivinini Esihamba Ngokushesha Inqola | 6000mm/min |

| 9 | I-Fixture Clamping Range | Φ40-350mm |

| 10 | Injini yokuphakela | 40N.m (Siemens AC servo motor) |

| 11 | Coolant System Motors | N=7.5kw 11kw 15kw |

| 12 | I-Hydraulic Pump Motor | 1.5kW,n=1440r/min |

| 13 | Ingcindezi Elinganiselwe Yesistimu Epholile | 2.5MPa |

| 14 | Ukugeleza Kwesistimu Yokupholisa | 237L/min, 201L/min,153L/min (3 amasethi) |

| 15 | I-Hydraulic System rated Pressure | 7 MPa |

| 16 | Ingcindezi Yomoya | ≥0.4MPa |

| 17 | Isistimu yokulawula | I-Siemens 828D |

| 18 | Ukunikezwa kwamandla kagesi | 380V.50HZ, 3 Isigaba (Enza ngendlela oyifisayo) |

| 19 | Isilinganiso somshini | L*2400*2100*( L*W*H) |

Izingxenye Zomshini Ezibalulekile

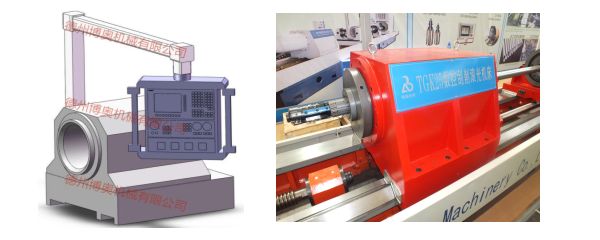

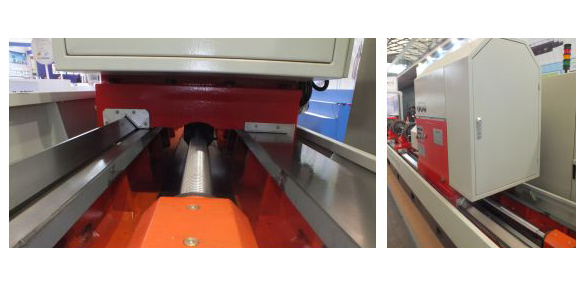

1. Umbhede Womshini

Lo mshini wokubhoboza imbobo ejulile usebenzisa isakhiwo sesitimela esiwunxande esiphindwe kabili.Umbhede waleli thuluzi lomshini wenziwe ngesihlabathi se-resin futhi uphonswe ngensimbi yekhwalithi ephezulu ye-HT300.Kungumshini oyisicefe onokubukeka okuhle namandla, okwenza ithuluzi lomshini libe nokumelana nokugqokwa okuhle nokugcinwa ngokunemba.Yenza umkhiqizo wokugcina uthole izilinganiso ezinembile zejometri.

2. Ibhokisi le-Boring Rod Drive

Ibhokisi lebha eliyisicefe liyisakhiwo sokusakaza esibalulekile futhi lifakwe kuphalethi lokuphakelayo.I-spindle ishayelwa i-servo motor engu-45KW AC, futhi ukujikeleza kwe-spindle kuqhutshwa ibhande elihambisanayo elishayelwa umshini wokushintsha isivinini.Ibanga lejubane liyi-3-1000r/min, amagiya angu-4, i-hydraulic automatic shifting speed regulation.Ukukhethwa kwejubane lokujikeleza kunganqunywa ngokusho kwezinto ezifana nempahla yokusebenza, ubulukhuni, ithuluzi lokusika kanye nesimo sokuphulwa kwe-chip.Ngokuya ngesivinini esihlukile, ingasethwa ngohlelo lokulawula izinombolo, futhi ama-spindle bearings akhethwa kumikhiqizo engenisiwe njenge-N SK yase-Japan.Umsebenzi oyinhloko webhokisi lebha eliyisicefe ukushayela ithuluzi ukuze lijikeleze.

3. Uhlelo Lokuphakela Amafutha

Lo mshini oyisicefe usebenzisa umjovo kawoyela nokubuya kukawoyela.Yenza ithuluzi lomshini ngokuqhubekayo linikeze uketshezi lokusika endaweni yokusebenza ngesikhathi senqubo yomshini, ngaleyo ndlela wenze inqubo yomshini ibe bushelelezi futhi ivikele isiqeshana somsebenzi.Idivaysi yokubuyisela uwoyela yenza amafutha okusika abe yisimo sokujikeleza ethuluzini lomshini, ukuze uketshezi lokusika engxenyeni yokucubungula luzothwala ama-chips emfucuza ebhokisini lokubuyisela.

4. Uhlelo lokuphakela ngomshini

I-Taiwan Shangyin i-screw screw yebhola enembayo ephezulu ifakwe phakathi nengxenye yangemuva ye-groove yomzimba wethuluzi lomshini, futhi kunebhokisi lokuphakelayo ekugcineni, elishayelwa yi-5.5KW AC servo motor, ukubona ukuphakelwa kwe- ithuluzi ngephalethi yokuphakelayo (ibhokisi lebha eliyisicefe).Ijubane lokuphakelayo lingashintshwa ngokunganaki, futhi ithuluzi lingahoxiswa ngokushesha.Ingxenye engaphambili ye-groove yomzimba wombhede womshini ifakwe isikulufu esimise okwe-T kanye nebhokisi lokuphakelayo, elisetshenziselwa ukondla idivayisi yokubuyisela uwoyela, ukulungisa indawo yokusebenza kanye nokubopha.Lonke uhlelo lokuphakelayo lunezinzuzo zokunemba okuphezulu, ukuqina okuhle, ukunyakaza okushelelayo, nokugcina ukunemba okuhle.

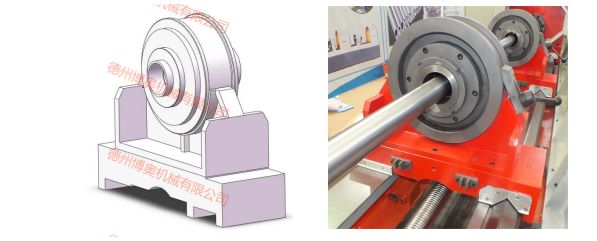

5. Uhlelo Lokusekela Ibha Eliyisicefe

Umkhono osekelayo webha eyisicefe ugxilwe emzimbeni wabakaki ngezikulufo, futhi uthathelwa indawo kanye nebha eyisicefe, elula futhi esheshayo esikhundleni semigoqo ehlukahlukene eyisicefe.Idlala kakhulu indima yokusekela ibha eyisicefe, ilawule indlela enyakazayo yebha eyisicefe, futhi ibambe ukudlidliza kwebha eyisicefe.Umkhono wosekelo wangaphakathi onokusebenza okujikajikayo.

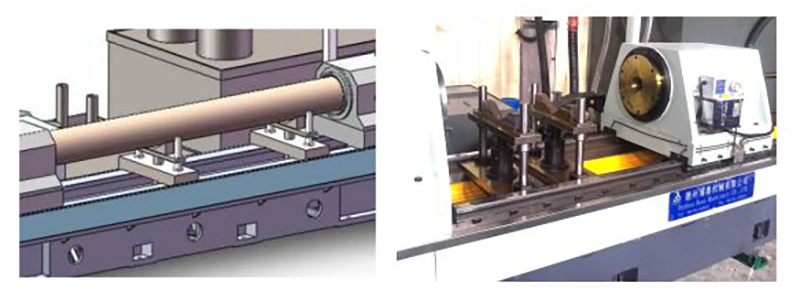

6. I-Workpiece Fixture Support System

Ifakwe amasethi amabili amabhlogo amise okwe-V ukusekela ucezu lokusebenza.Isikulufu nokuphakamisa amantongomane kungalungiswa ngokuzenzakalelayo ngokuya ngamadayimitha ahlukene wocezu lokusebenza.Ngokuyinhloko idlala indima yomthwalo we-workpiece kanye nokulungiswa, kanye nokuma kwembobo eyisicefe

7. IHydraulic System

Ithuluzi lomshini lifakwe uhlelo olukhethekile lwe-hydraulic, olusetshenziselwa ukulawula ukunwetshwa nokufinyezwa kwethuluzi le-hydraulic kanye nokuguquguquka okuzenzakalelayo kwe-hydraulic kwebhokisi le-bar eyisicefe ukuqedela uhlelo lokulawula lwesenzo sokugoqa.Ingcindezi elinganiselwe ingu-7Mpa.Izingxenye eziyinhloko yimikhiqizo yochungechunge locwaningo lwamafutha angaphandle.

8. Uhlelo Lokuhlunga Okupholisayo

Ukukhishwa kwe-chip yokupholisa kanye nesistimu yokuhlunga: ikakhulukazi etholakala ngemuva kwethuluzi lomshini, ngemva kokuhlunga ngomshini wokukhipha i-chip othomathikhi we-chain plate (isihlungi esimahhadla)→isihlungi sikawoyela esisezingeni lokuqala→isihlungi sikawoyela sezinga lesibili kanye nokuhlunga kwelesithathu ngemva kokuthungwa kanye ukuhlunga.Amashidi ensimbi athunyelwa emotweni yokugcina ama-chip ngesidluliseli se-chip plate, isipholile sigeleza sibuyele ethangini likawoyela, bese okokupholisa kunikezwa kumamukeli kawoyela ngesiteshi sepompo sokupholisa, futhi uwoyela uhlinzekwa ngamasethi angu-3. wamaphampu ane-vane ukuhlangabezana nezidingo ezahlukene zosayizi wembobo yesiqeshana sokusebenza.

Lapho kwenziwa umgodi ongaphakathi we-workpiece, i-shaft eyinhloko yebhokisi le-bar eyisicefe ishayela ithuluzi ukuze lijikeleze, futhi ama-chips ensimbi aqhutshelwa phambili yi-coolant futhi akhishwe ngembobo yangaphakathi yedivayisi yokubuyisela uwoyela.Umshini ozenzakalelayo wokukhipha ama-chip uthumela ama-ayina amashidi emotweni yokugcina ama-chip, futhi okokupholisa kuyaqoqwa futhi kuphinde kusetshenziswe kabusha.

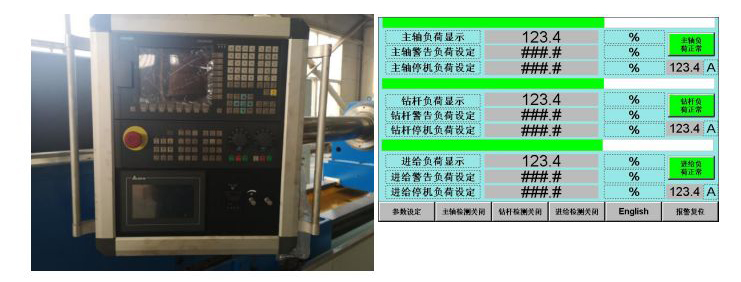

9. Ukusebenza komshini

Iphaneli yokulawula ukusebenza kwethuluzi lomshini ifakwe esihlalweni sokucindezela futhi igxilwe kunqola yesihlalo esicindezelayo, esilungele ukusebenza kwethuluzi lomshini.Iphaneli lenziwe ngensimbi engagqwali ye-matt brushed, ukwakheka kuhlangene ngokuphelele, kuhle futhi kuhlala isikhathi eside.

Isoftware yomshini yakhelwe ku-Siemens futhi isetshenziswa iminyaka eminingi.Sihlala sithuthukile njengezinga lomhlaba jikelele.

10.Isistimu kagesi

Iqukethe ibhokisi lokulawula eliyinhloko, ibhokisi lokusebenza, ibhokisi letheminali kanye nezintambo.Izingxenye zikagesi eziyinhloko yi-Schneider brand.Okwebhokisi lokulawula likagesi (ukupholisa umoya we-air conditioning).Ingxenye enkulu yezintambo isebenzisa isakhiwo sepulaki yendiza.Izintambo zisebenzisa izinga likazwelonke, futhi izintambo zamanje ezibuthakathaka zisebenzisa izintambo ezivikelekile.I-wiring ihlelwe ngokuhambisana ngokuqinile nokuhlukaniswa kukagesi okuqinile nokubuthakathaka.

| NO | Izinto | Amabhrendi | NO | Izinto | Amabhrendi |

| 1 | Umzimba wensimbi womshini | Uzenzele | 2 | Boring bar drive box | Uzenzele |

| 3 | Iphaneli yokusekela | Uzenzele | 4 | I-spindle bear | Japan NSK |

| 5 | Amanye amabhere | Imikhiqizo emihle | 6 | Isikulufu sebhola | I-brand yaseTaiwan |

| 7 | Izakhi zikagesi eziyinhloko | schneider noma siemens | 8 | I-spindle motor | China brand |

| 9 | Okuphakelayo servo motor | Siemens | 10 | Okuphakelayo umshayeli we-servo | Siemens |

| 11 | Uhlelo lwe-CNC | Siemens | 12 | Izakhi zomoya | Japan SMC |

10.CNC Control System

Ithuluzi lomshini lifakwe isistimu ye-SIMENS CNC ene-RS232/USB interface, engahlelwa ngaphandle komshini.Ifakwe okokufaka kohlelo nokukhipha isikhombimsebenzisi, esingadluliselwa kukhompuyutha.Lungiselela iphaneli yokulawula eyinhloko nesiteshi senkinobho yokusebenza, isixhumi esibonakalayo sokusebenza kwesiShayina kanye namaswishi okusebenza, izinkinobho, njll. Yenza ithuluzi lomshini libe nemisebenzi yokuphakela mathupha kanye nemisebenzi yokuzihlola.Isibonisi sesimo, isibonisi sendawo yamanje, isibonisi sohlelo, isibonisi sezilungiselelo zepharamitha, isibonisi se-alamu, ukuguqulwa kwesibonisi sezilimi eziningi neminye imisebenzi.Ukulungiselelwa kwepharamitha kulula, kunembile, kulula futhi kuthembekile.Imojula yomsebenzi wokuvikela ithuluzi le-PLC yengezwa ukuze kugwenywe ngempumelelo into "yokubamba ummese".